THE PRINCIPLE OF THE EXCHANGE SYSTEM

NO TRANSPORT OF EMPTY BOXES ANYMORE

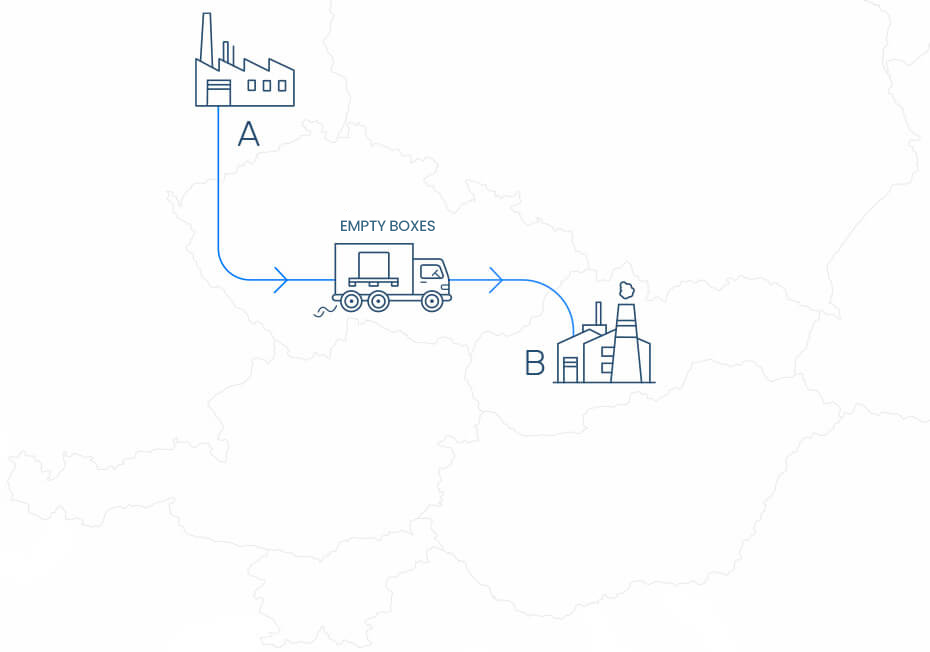

Diagram 1 illustrates a commonly used uneconomical method of transporting empty Euro cage pallets from point A to point B

MAIN DISADVANTAGES OF THE SAID METHOD:

SOLUTION

THE PRINCIPLE OF OUR EXCHANGE SYSTEM FOR EURO CAGE PALLETS

In order to help our customers reduce the costs associated with the transport of empty boxes, optimize logistics processes and contribute to a reduction of CO2 emissions, we offer an exchange system coordinated by our company (diagram 2).

Thanks to our company’s dense network of collection and distribution points, we can significantly shorten transport distances in this way, thereby reducing transport costs and contributing to a reduction of CO2 emissions.

BENEFITS OF THE EXCHANGE SYSTEM

COST & CO2 EMISSIONS REDUCTION

THE EXCHANGE SYSTEM OFFERS

SUBSEQUENT TRANSPORT PACKAGING